Selective laser sintering (SLS) is a state-of-the-art additive manufacturing technology / 3D printing technique

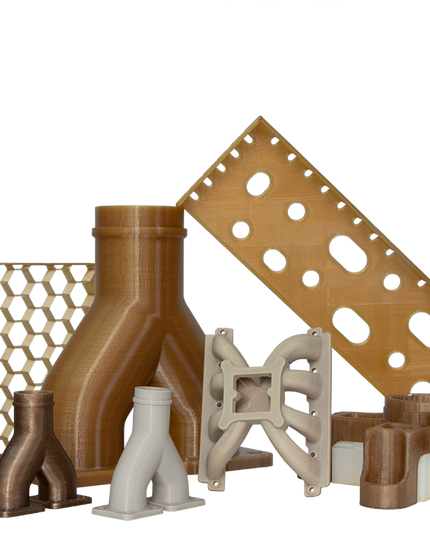

Selective laser sintering offers several advantages over traditional manufacturing methods, including the ability to create complex geometries with high precision, excellent mechanical properties , and the freedom to use a wide range of materials. This makes it a popular choice for producing prototypes, custom parts, and production runs across a variety of industries, including aerospace, automotive, healthcare, and consumer goods.

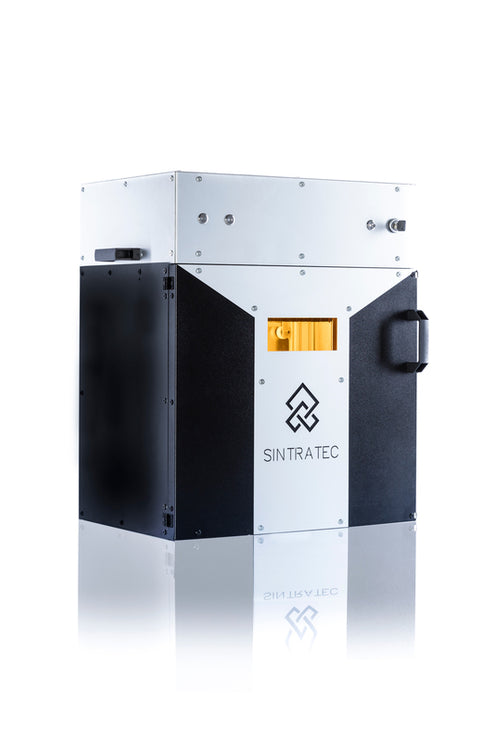

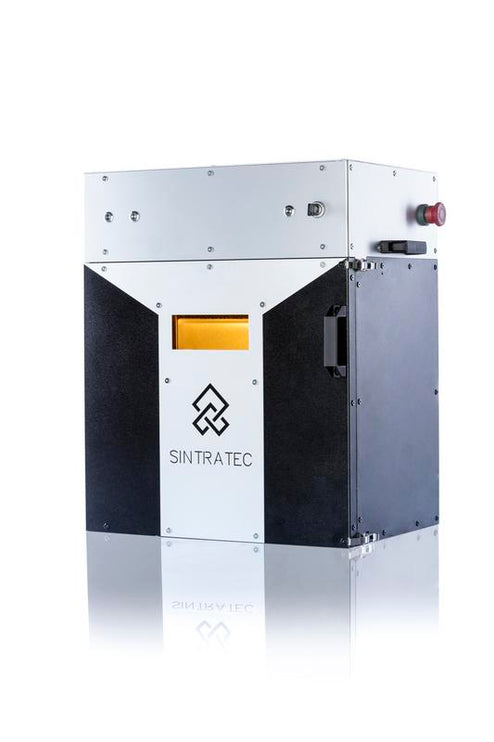

An SLS 3D printer uses a powerful laser to fuse together small particles of powdered material to create intricate three-dimensional objects. Compared to other techniques, the advantages of SLS 3D Printing are compared to FDM and SLA technology.

High level of detail and strength. Strong - Racing car parts made with SLS technology

Complete freedom as a designer!

Advantages of SLS Technology.

- Can create extremely complex geometries, no support structures needed

- Parts created with SLS Technology have higher strength, comparable to a molded part

- Objects created with laser sintering are very strong, it is not noticeable that the part is made on a 3D printer

- Multiple parts integrated into the same model can be created easily. For example, a model consisting of two parts that fit together. No retrofitting required

- Sintratec S3 supports metal printing, so-called cold fusion

- Has high precision and tolerances within approximately +- 0.5%.

SLS - Limitations: Few materials, few colors, models can be dyed afterwards with fabric dye!

-

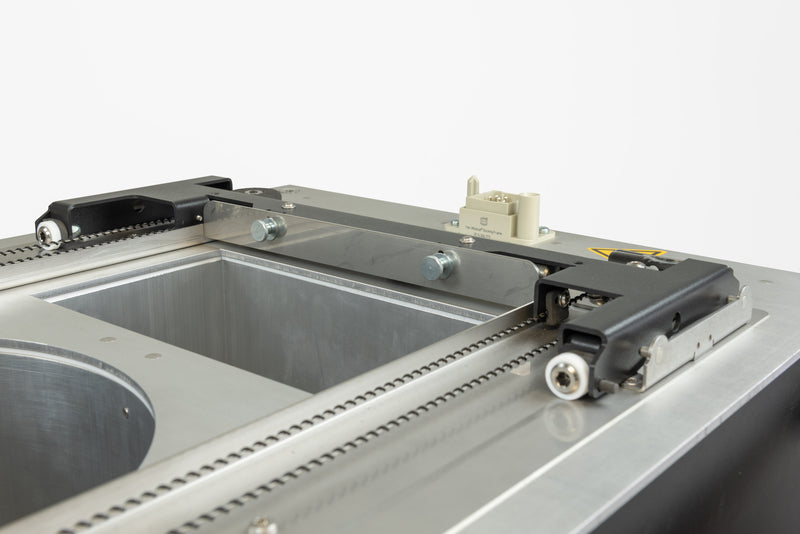

Powder-based material:

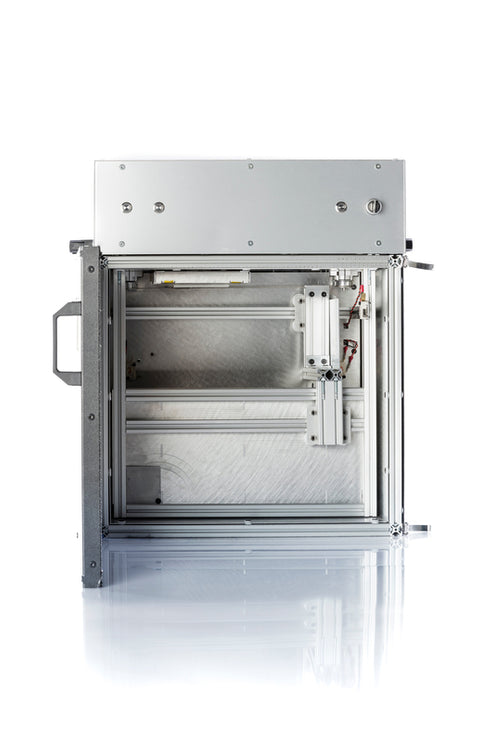

SLS begins with a layer of powdered material, usually plastic powder such as polyamide (nylon), plastic, metal or ceramic. This powder also serves as the building material and support structures for the object to be printed.

-

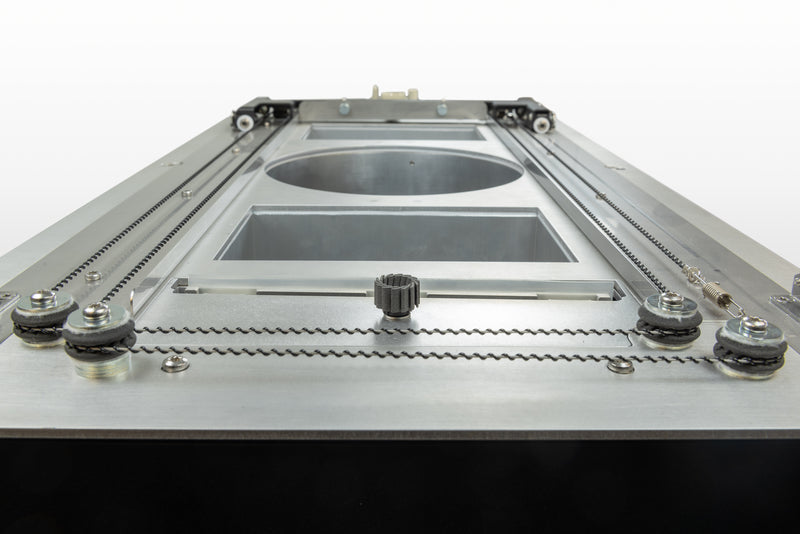

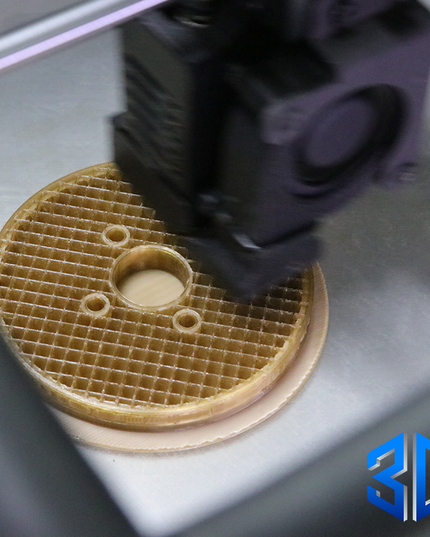

Selective fusion

A high-precision laser scans and fuses the powdered material according to a digital drawing of the object being created. The laser beam traces the cross-section of the object on the powdered layer and causes the particles to fuse together at precise points.

-

Layer-by-layer construction :

After a layer is completed, the build platform is lowered by a fraction of the layer's thickness, and a new layer of powder material is spread over the previous layer. The laser beam then fuses this new layer with the previous layer. This process is repeated until the entire object is constructed, layer by layer. - Finishing :

Once the print is complete, the models in the build chamber need to cool down. The printed object is then carefully removed from the remaining powder in a material handling station (MHS). Some of the remaining powder can be recycled

for future printing.

-

Further finishing

Once the models are cleaned, the parts need to be cleaned of traces of powder. This is done using a blasting station.

-

Alternative finishing

Then, depending on your wishes, the models can also be finished with various finishing techniques such as grinding, polishing or painting to achieve the desired surface.

-

Polyamide (Nylon / PA12): The most widely used SLS 3dprinting material on the market, used for parts created in industry and production using SLS printers. PA12 is tough, slightly flexible, melts at 185ºC

-

Polyamide 12-GF (Glass filled) The nylon material is combined with glass, providing higher strength, a stiffer and more durable part, and slightly higher heat resistance.

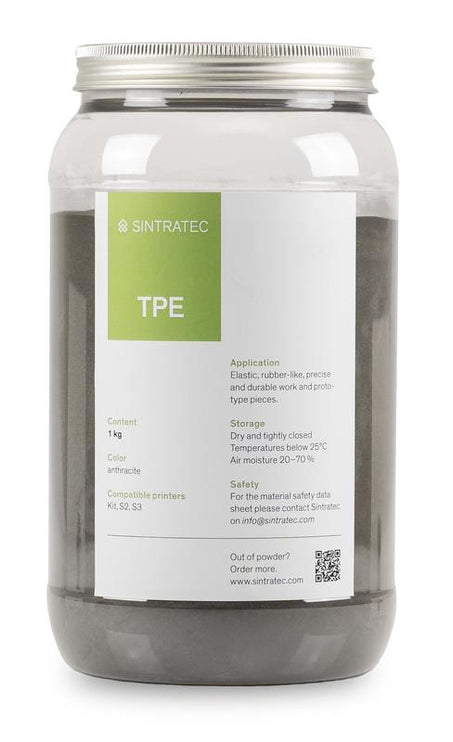

- TPE (TPU): Sintratec TPE powder is an elastomer that creates flexible, rubbery parts. The material is impressively stretchable and can withstand ruptures of up to 448%. TPE is an industrial grade material well suited for applications that require a high degree of ductility. (That is, the material can be stretched/bent without the material becoming defective or breaking)

- Other materials: Sintratec AMP system can be used with most materials available on the market but may require optimization. Contact us for more info.

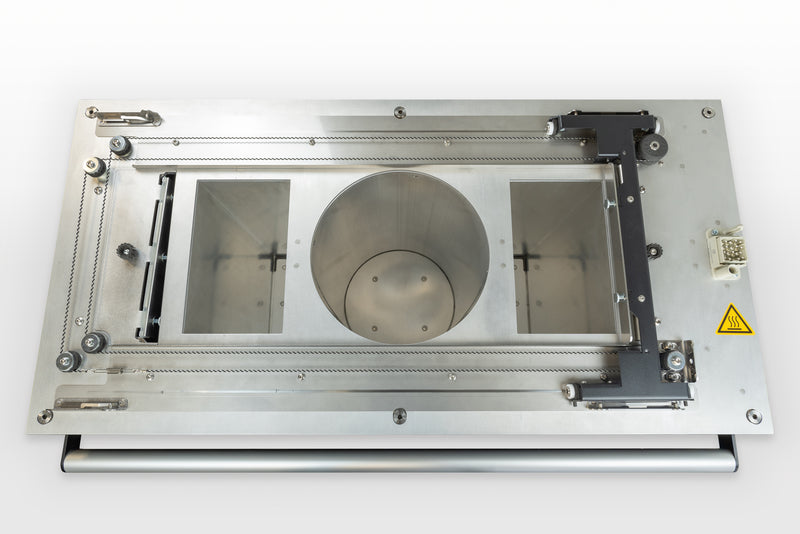

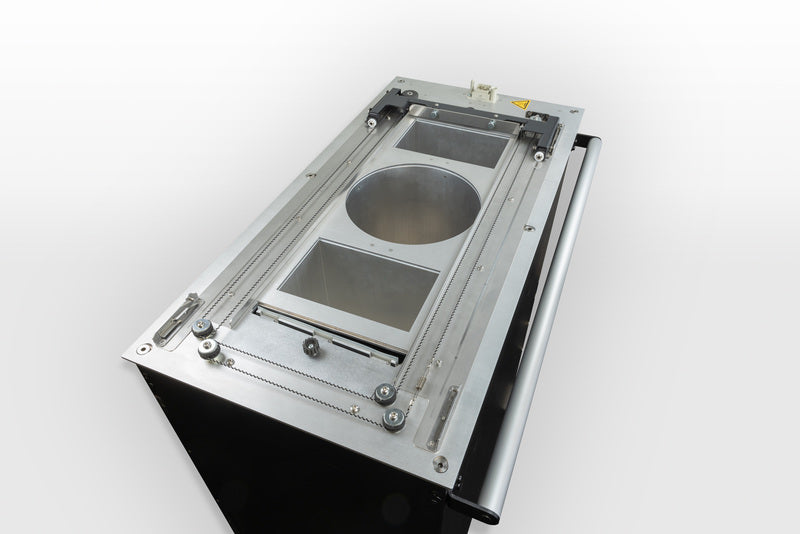

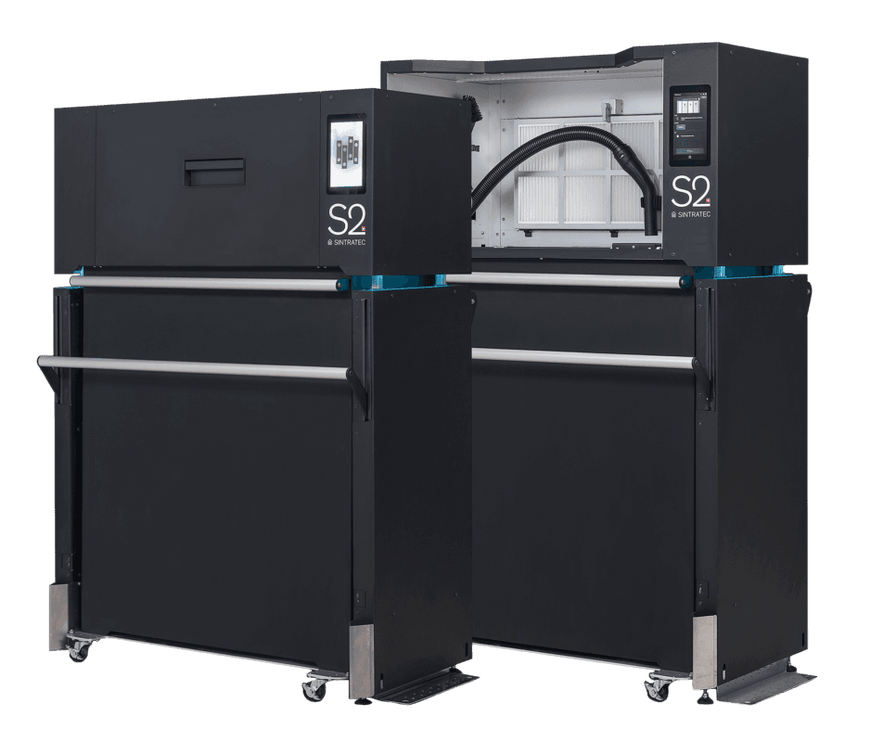

- We use Sintratec S3 and MCU220 which can handle models with sizes up to ⌀220x400mm.

- Sintratec S3 & S2 can also be used with MCU160 which can handle ⌀160x400mm

- The Sintratec Kit has a construction volume of max. 110x110x110 mm

- We use Sintratec S3 and MCU220 which can handle models with sizes up to ⌀220x400mm.

- Sintratec S3 & S2 can also be used with MCU160 which can handle ⌀160x400mm

- The Sintratec Kit has a construction volume of max. 110x110x110 mm

-

Polyamide (Nylon / PA12)

The most widely used SLS 3D printing material on the market, used for parts created in industry and production using SLS printers.

PA12 is hard, slightly flexible, melts at 185 ºC -

Polyamide 12-GF (Glassfilled)

The nylon material is combined with glass, providing higher strength, a stiffer and more durable part, and slightly higher heat resistance. -

TPE (TPU)

Sintratec TPE powder is an elastomer that creates flexible, rubbery parts. The material is impressively stretchable and can withstand ruptures of up to 448%. TPE is an industrial grade material well suited for applications that require a high degree of ductility. (That is, the material can be stretched/bent without the material becoming defective or breaking)

-

Other materials

Sintratec AMP system can be used with most materials available on the market but may require optimization. Contact us for more info

We at 3D-part specialize in additive manufacturing and can help you whether you just want to get a few parts 3D printed or if you need your own system.

We help you with:

- SLS 3D printing on demand (When it is not profitable to have your own system)

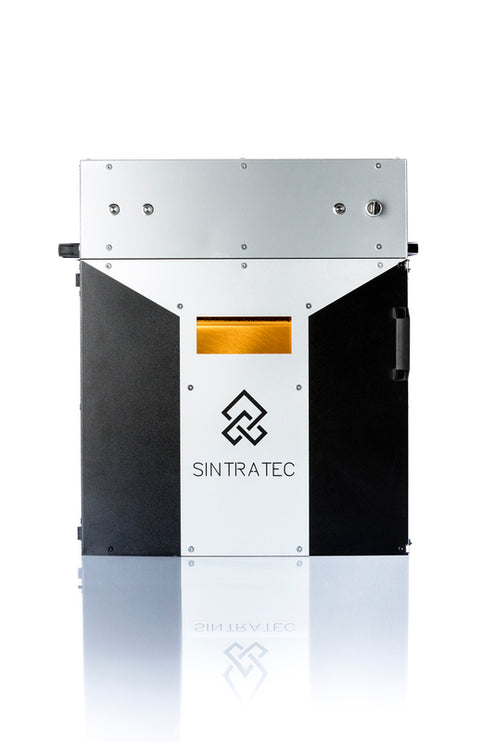

- SLS complete package - Buy Sintratec SLS system from us. We help you secure your local production through

- SLS 3D training

- Service & maintenance agreements

- Contact us for consultation