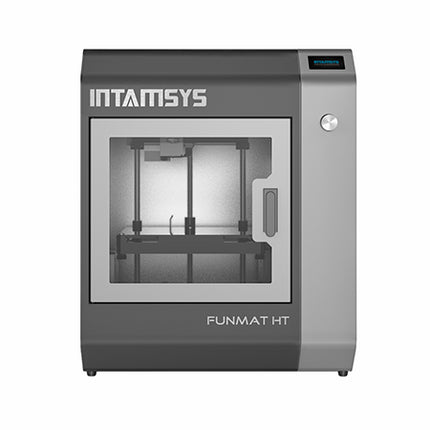

FDM Printer

FDM - Fused Deposition Modeling and is one of the most common 3D techniques in additive manufacturing.

What is FDM printing? How does this technology work?

FDM 3D technology is a revolutionary technology that has changed the manufacturing landscape, enabling the creation of complex plastic models with precision and efficiency. Let's describe more about how FDM printing works and the magic behind this fascinating process.

At the heart of FDM technology is a simple but ingenious process that brings digital designs to life layer by layer by melting a plastic thread called filament . This plastic thread comes in two standards, the most common being 1.75mm and the other being 2.85mm. Brands such as Ultimaker and BCN3D primarily use 2.85mm filament.

The plastic filament for 3D printers comes wound on different types of rolls and usually has a weight of 0.25-10KG.

For large 3D models we stock and use 2.1kg, 5kg, 10kg rolls

How does FDM technology work?:

-

Digital design : It all starts with a digital 3D model created using computer-aided design (CAD) software. This design serves as the blueprint for the object you want to create.

-

Printing process : The digital model is then converted into a software called a slicer. The slicer converts your 3D model into a so-called .GCOD file.

The file is then uploaded to the 3D printer and printing can begin. The printer then works through these coordinates and builds the model one layer at a time until it is complete.

The .GCODE file contains a description with calibration values and coordinates for how the FDM printer's nozzle should move. -

Material selection : FDM printers use various thermoplastics in the form of a plastic filament of 1.75 or 2.85mm. The most common FDM printing materials are PLA filament , ABS , PETG etc. The materials come wound on rolls and are available from 250g to 10KGs rolls.

-

Heating and Extrusion : The FDM printer heats the filament to its melting point within a heated nozzle called an extruder. Once melted, the material becomes liquid and can be extruded through a fine nozzle in precise patterns.

-

Layer-by-layer deposition : The printer nozzle moves along the X, Y, and Z axes according to the sliced layers, depositing molten material onto the build platform. As each layer is laid down, it bonds to the previous layer, gradually building up the object.

-

Cooling and solidification : Once the extruded material is deposited, it quickly cools and solidifies, retaining its shape and integrity. This process ensures that each layer adheres firmly to the previous one, creating a stable and durable final product.

-

Support structures (if needed) : In some cases where the 3D design requires overhangs or complex geometries, the printer may include temporary support structures made of the same material. These supports provide stability during printing and can be easily removed once the print is complete. If you have a printer with dual print heads, you can use a water-soluble support material for best results.

-

Completion : Once all layers are deposited and the object is fully formed, the build platform is lowered and the completed object can be removed from the printer. Depending on the complexity and size of the object, printing can take anywhere from a few hours to several days.

Example of printing with fiberlogy filament.

FDM 3D printing offers unparalleled versatility and is widely used across industries including aerospace, automotive, healthcare and consumer goods. Its ability to create functional prototypes, custom parts and intricate designs with speed and precision has made it a cornerstone of modern manufacturing.

Explore the endless possibilities of FDM 3D printing technology and bring your imagination to life with our cutting-edge technology and expertise. Whether you are a hobbyist, designer, engineer or entrepreneur, FDM 3D printing opens up a world of innovation and creativity. Fused deposit molding (FDM) is often referred to as FFF, Fused filament fabrication

Contact us today to learn more about how FDM 3D machines can revolutionize your manufacturing process in a cost-effective way!

Order 3d model made of plastic

We do contract manufacturing in plastic with a wide range of materials, can also be combined with metals, sheet materials, etc.

We have several 3D techniques

- Manufacturing with Selective laser sintering

- Manufacturing with Fused deposit molding

- Manufacturing with Stereolithography